Chemigate has begun construction on a new production plant for polysaccharide processing in Lapua. This significant investment is also a step towards even more environmentally sustainable products.

The construction of the new production plant has been carefully prepared for a year.

In part, it has to do with the company’s cooperation with International Flavors & Fragrances Inc., which was presented in issue 1/2021 of Chemigate’s The Bridge customer magazine.

With this project, Chemigate will expand its production and raw ingredient selection into a whole new area.

Chemigate is known as a trailblazer in the field of modified starches for technical applications and starch-based cationic chemistry. Now, they plan to apply and expand this special expertise to processing other sugar-based raw ingredients.

This is a significant project for the environment, built on a new product refined from polysaccharides. It will play a key role in end-user innovations designed for replacing oil-based products and sources of microplastics, for example.

The new modification plant will create a whole new business for Chemigate, independent from any starch raw materials and applications of the paper and cardboard industry. It will have no impact on the demand for starch or Chemigate’s starch production, which will continue as normal.

A new milestone on the path towards sustainable development

According to Chief Technology Officer Aki Laine, the new modification plant will be one-of-a-kind – even on a global scale.

“This is a new opening to the market, as this type of polysaccharide has never been produced or modified on an industrial scale before. At the same time, our business will expand to other technical applications outside the paper industry. The idea is to manufacture a bio-based, bio-degradable and microplastic-free component for our partners’ many purposes.”

The construction project, worth about €6-7 million, is Chemigate’s largest investment since the dry starch modification plant completed in 2012.

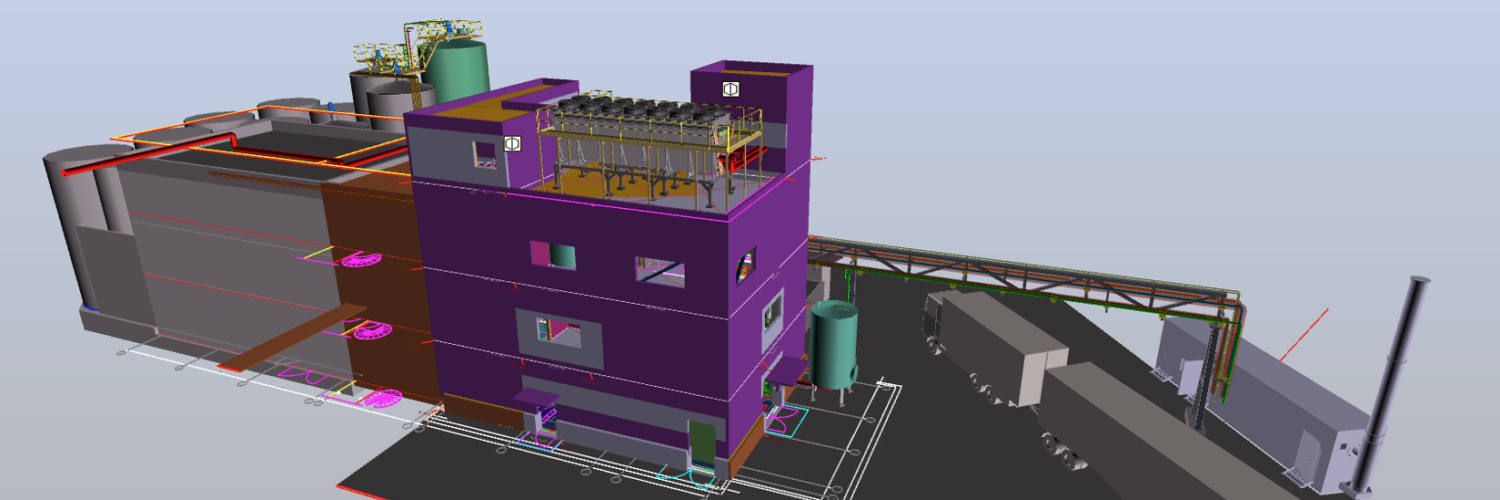

“In this project, we will expand the wet modification plant in Lapua by approximately 50% by adding a new wing. The hardware in the current plant will be partly used for future production, which is largely based on chemistry similar to starch processing,” says Laine.

The new modification plant’s construction was launched in August with earthworks and now, in October, the work has proceeded to building the foundations. According to the schedule, the plant will be commissioned in late summer 2022.